Successful technology exchange for the e-mobility and battery industry

Tech Days India, organized by ViscoTec India in cooperation with VDMA India and partners Bostik and TOX India, provided a high-caliber platform for decision-makers in the Indian e-mobility and battery industry in November 2025. With 115 registered participants from a wide range of industry segments, the event confirmed the rapidly growing interest in efficient production processes for electric drive systems.

Dynamics in the Indian e-mobility sector

India is currently experiencing particularly dynamic development in the e-mobility market – especially in the area of battery and module production. The adoption of modern technologies, especially in the rapidly expanding 2-wheeler segment, is gaining momentum. That is why ViscoTec India’s goal was to offer users practical insights into advanced dosing technologies and to jointly develop solutions for current and future challenges facing the industry.

“Our aim was to create a technically oriented event that would give our customers realistic insights into modern dosing technology,” explains Vivek Ghewari, Branch Manager of ViscoTec India. “We wanted to show how our systems solve typical dosing challenges – reliably, precisely, and with future-proof solutions.” The combination of material expertise (Bostik), mechanical engineering expertise (TOX India), and dosing technology (ViscoTec) enabled a unique event format that covered the entire process chain.

Focus on technology: Live demonstrations with practical relevance

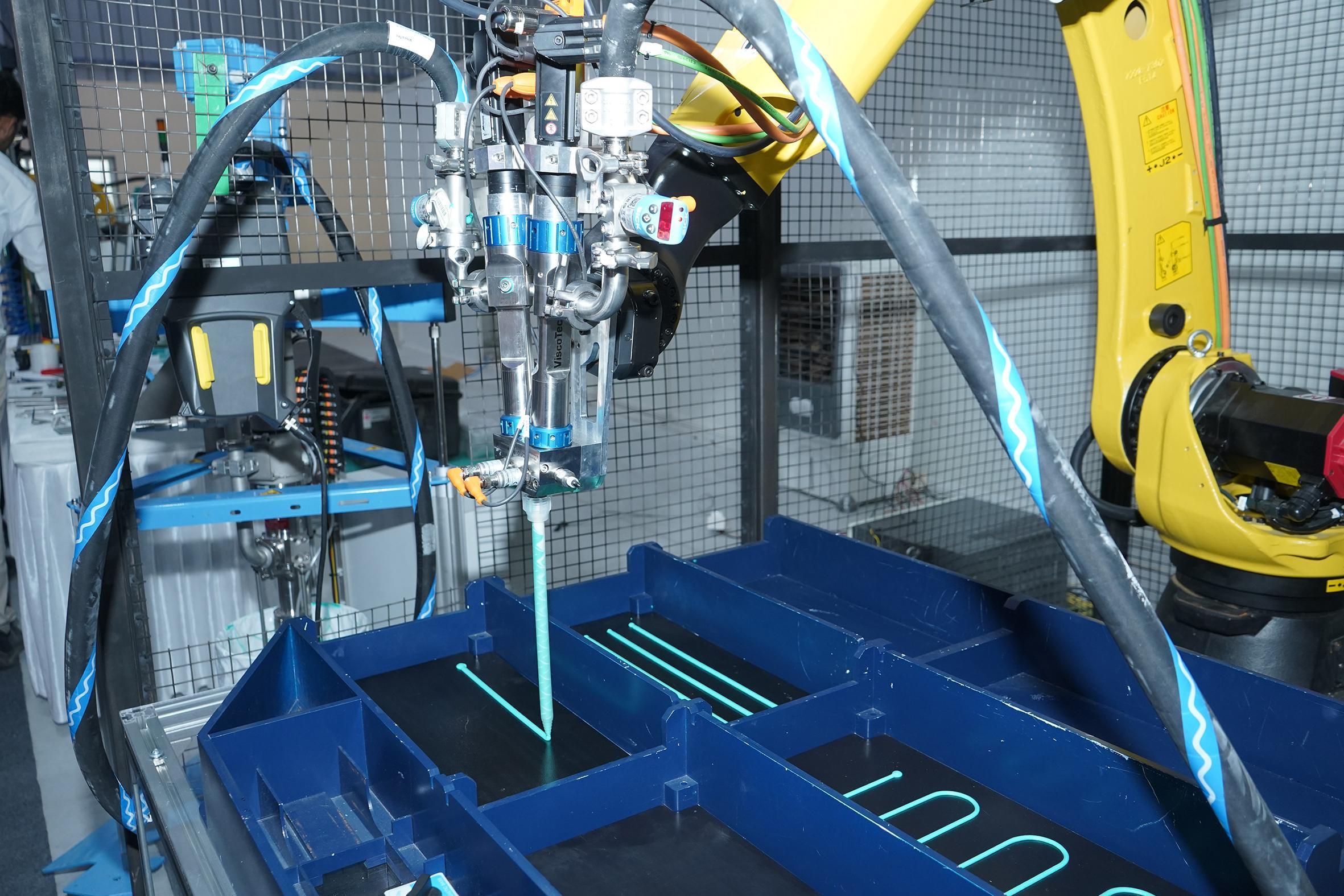

A particular highlight was the live demonstrations of ViscoTec metering pumps based on eccentric screw technology. Applications presented included:

- Single- and two-component gap fillers with high filler content and good thermal conductivity, which are used in the thermal management of battery packs

- MMA chemicals, which are used in structural adhesive applications and offer fast curing mechanisms

Visitors gained in-depth insights into complete process sequences – from material delivery to high-precision application. The independence of ViscoTec technology from viscosity, temperature, and pressure attracted particular attention. Many participants took the opportunity to discuss differences from conventional systems such as time-pressure, jetting, or piston technologies.

Focus on cost-effectiveness and future-proofing

In addition to technical performance, two topics were clearly the focus of discussions with trade visitors:

- Return on investment: Despite higher initial investments, companies wanted to understand how ViscoTec systems reduce operating costs and minimize maintenance expenses in the long term.

- Flexibility for future production lines: In view of ever shorter investment cycles, adaptability to new materials, process variants, and product generations plays a decisive role.

Growing market presence through direct exchange

The Tech Days offered ViscoTec India the opportunity to further intensify its dialogue with OEMs as well as Tier 1 and Tier 2 suppliers. The close cooperation with Bostik and TOX India was perceived by many participants as a great added value, as it combined expertise from three key areas of competence: dosing technology, material technology, and automation. This strengthens ViscoTec’s position as the preferred partner for demanding dosing processes in Indian industry in the long term.

The use cases presented reflected the familiar trends in the Indian market. The team gained valuable insights – particularly through cross-functional collaboration within the global ViscoTec network and intensive exchange with event partners. “For us, the event was a success in every respect – organizational, technical, and strategic,” summarizes Ghewari.

Based on the positive feedback, ViscoTec India plans to offer the successful format in other regions in the future. Concrete inquiries have already been received, particularly from western India.