3D Print Heads

SOLUTIONS FOR YOUR EXTRUSION-BASED ADDITIVE MANUFACTURING.

ViscoTec 3D print heads are suitable for high-precision printing of one- and two-component media. The design of the print heads with the proven endless piston principle allows the processing of pastes with a viscosity of up to 1,000,000 mPas. In the appropriate configuration, even media filled with abrasive fillers can be processed reliably. The print heads can be easily connected to almost any 3D printer. The control is “plug and play” via the signals of the 3D printer. Our dosing heads expand the range of applications of your 3D printer with minimal effort in the field of fluid printing. You can use them to print silicones, UV adhesives, ceramic pastes, polyurethanes, epoxy resins and metal pastes.

Learn more in our whitepaper and our applications on additive manufacturing with liquid materials.

Industrial 3D printing with ViscoTec 3D print heads

Exact, clean, automatic and repeatable: For precise material handling.

- Gentle product conveyance of the material

- Volumetric dosing

- Precise start and end points

- Programmable suck-back function

- Dosing regardless of viscosity

- Dispensing accuracy of up to 99%

- Low-maintenance and durable print head

vipro-HEAD Series

3D Print Heads for 1-component Materials

vipro-HEAD 3 and vipro-HEAD 5

- Theoretical volumetric flow: 0.03 – 6.0 ml/min

- Weight: about 500 g

- Optional heating function up to 70°C

- Dosing materials: UV adhesives, epoxy resins, acrylate, silicone, grease, inks, waxes, ceramics, bio-technical suspensions, abrasive pastes and others

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information3D Print Heads for 2-component Materials

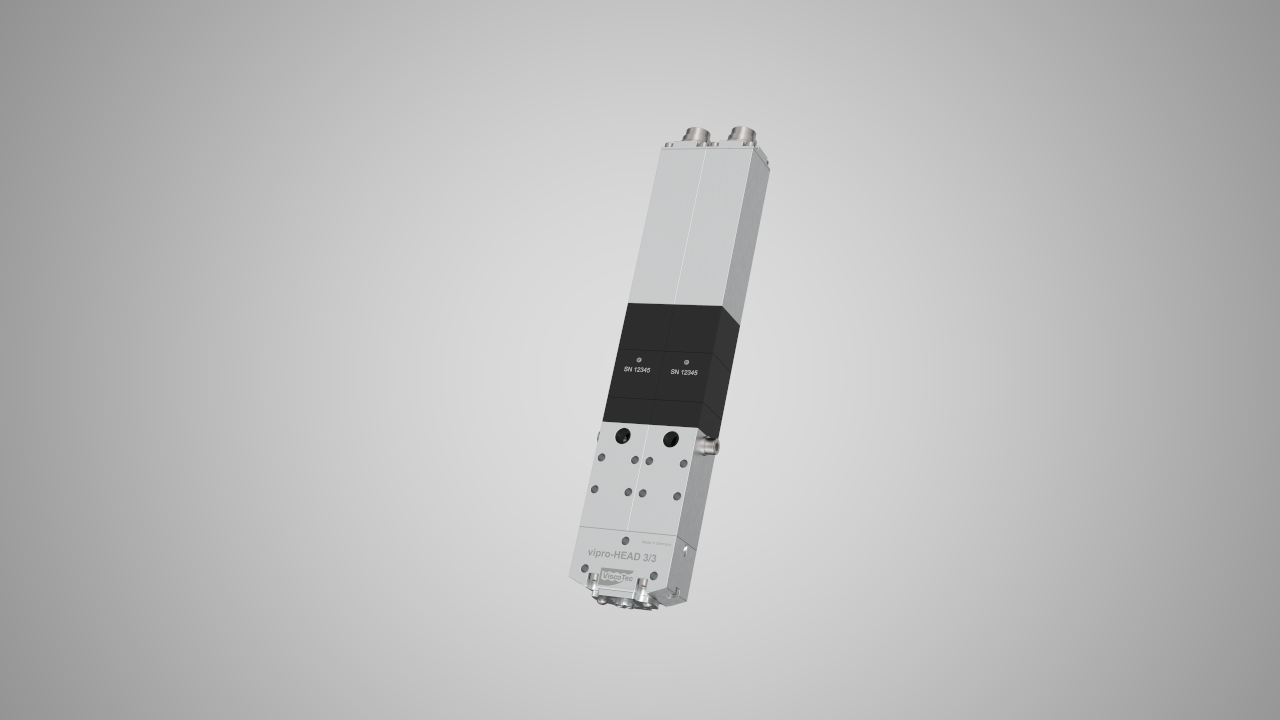

vipro-HEAD 3/3 and vipro-HEAD 5/5

- Theoretical volumetric flow: 0.03 – 6.00 ml/min per mixing head part

- Mixing ratio: 1:1 to 5:1 (depending on dosing material, viscosity, pre-pressure and mixing ratio)

- Weight: about 1,100 g

- Dosing materials: Epoxy resins, acrylate, silicone, polyurethane, polyester resins and others

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationFeatures

vipro-HEAD color

- Ink delivery system for color pigments and additives (0.5 – 3%)

- Theoretical volumetric flow: 0.03 – 3.3 ml/min

- Weight: about 600 g

- Modular concept for an easy upgrade of the whole print head vipro-HEAD series

You can find further information about the ink delivery system here and in the video below.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information