ViscoTec presents new L-Series and proven dispensing solutions

At productronica, ViscoTec will showcase both well-established and newly developed products that further enhance the dosing technology specialist’s portfolio. In addition to existing dispensing solutions and rotor variants, the new vipro-PUMP L and vipro-DUO L dispensers, as well as the new vipro-FEED L plus emptying system, will be introduced.

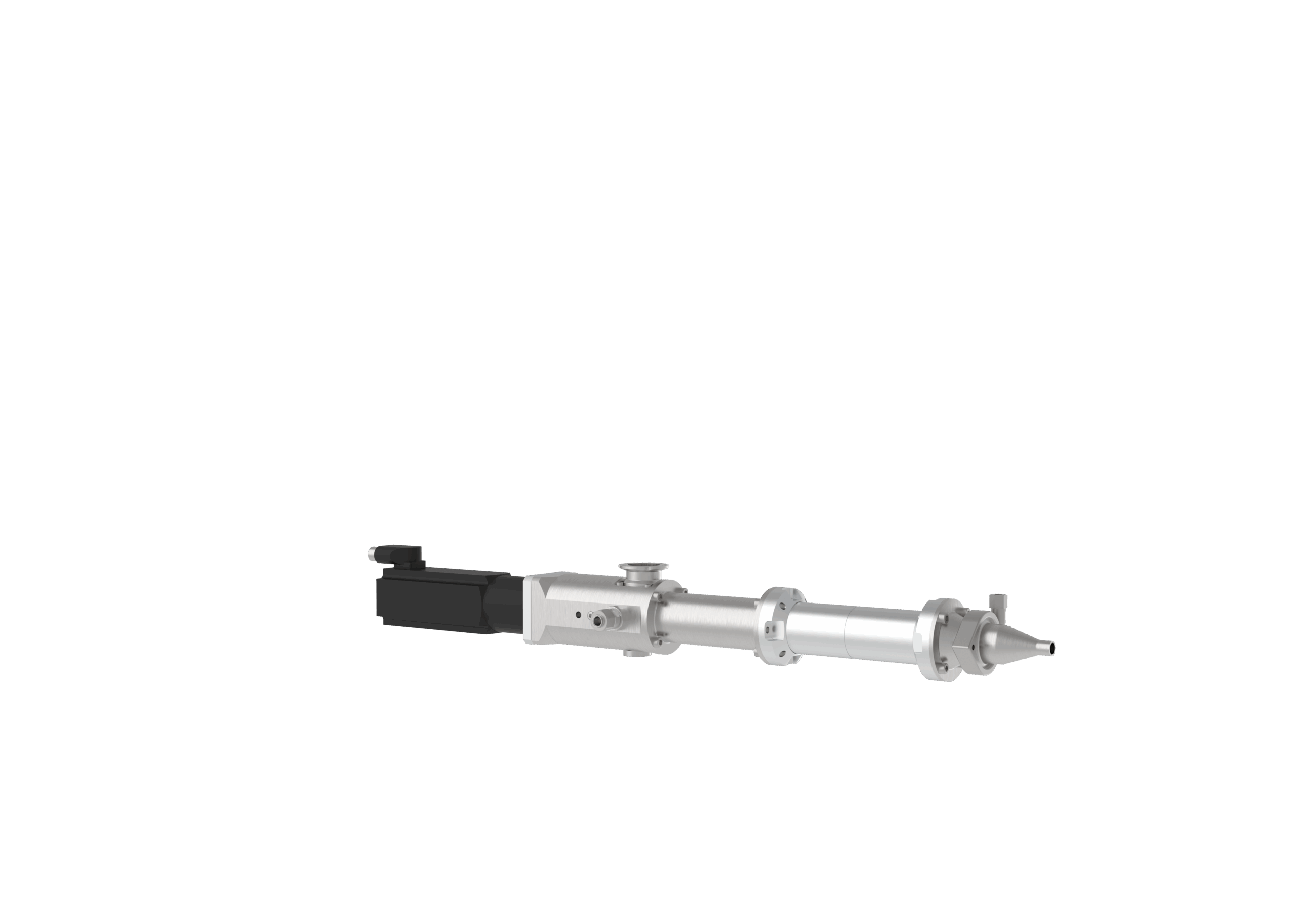

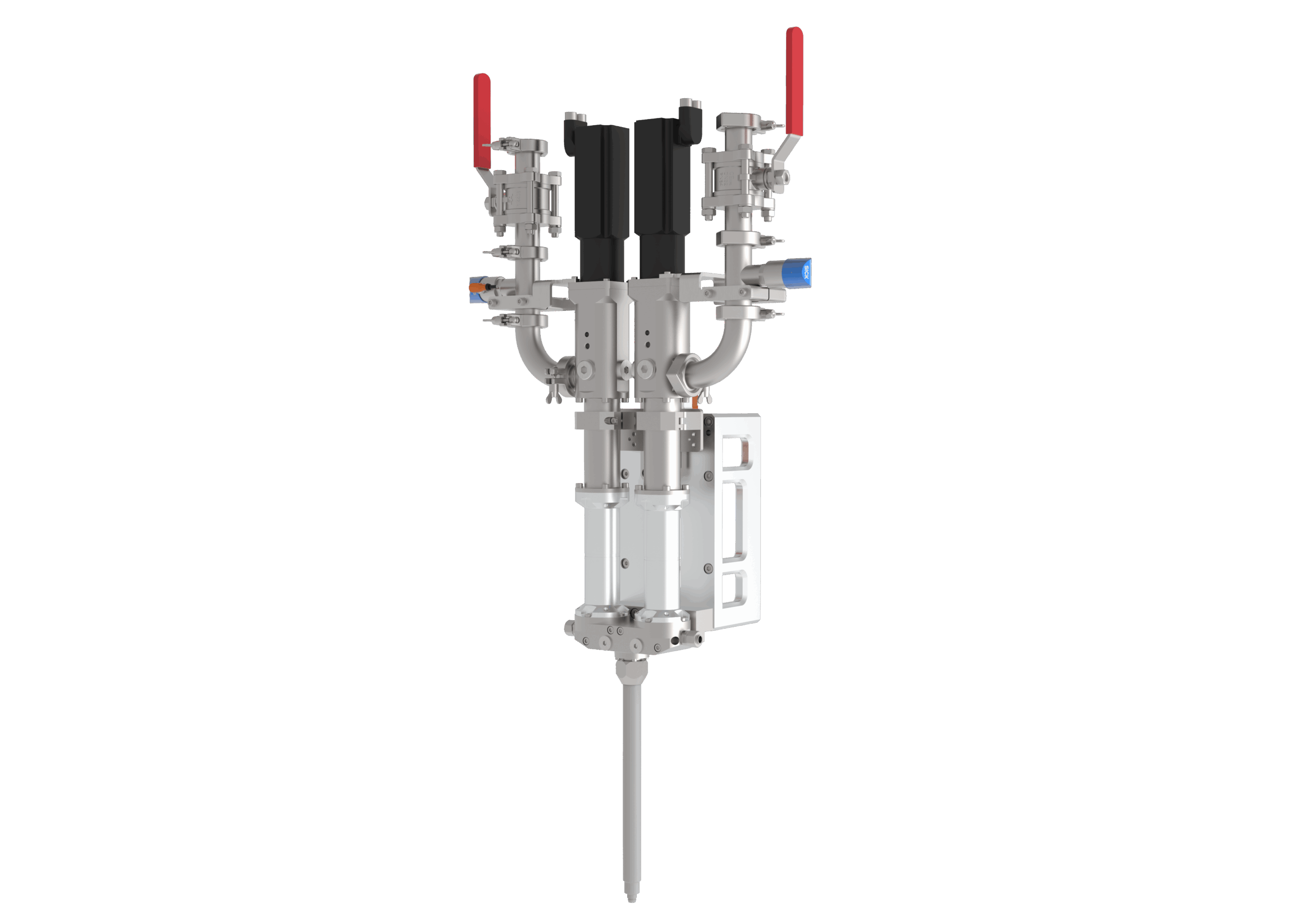

vipro-PUMP L and vipro-DUO L: Proven precision and smart features

The vipro-PUMP series of dispensers is now expanded with the 1-component vipro-PUMP L and the 2-component vipro-DUO L models. The modular design of the vipro-PUMP has now been applied to the large-scale dispenser series as well. This ensures optimized handling and reduced spare parts costs, even with high dispensing volumes. As with the existing models, the improvements guarantee uninterrupted dispensing with the highest accuracy requirements, using endless piston technology. For users, this means proven precision combined with innovative design and smart features. The result: maximum process reliability, less downtime – and noticeably greater efficiency in everyday dispensing operations.

Your benefits with the vipro-PUMP L series:

- Simpler handling – defined stator position, effortless repositioning, and clean venting ensure smooth operation.

- More precision, more safety – integrated sensors continuously monitor the process and guarantee consistent dispensing quality.

- Impressive productivity – efficient service and durable, abrasion-resistant components ensure maximum reliability and increase system uptime.

When combined with the vipro-FEED M & L plus emptying systems, the 1-component or 2-component dispensers form a perfectly coordinated dosing system.

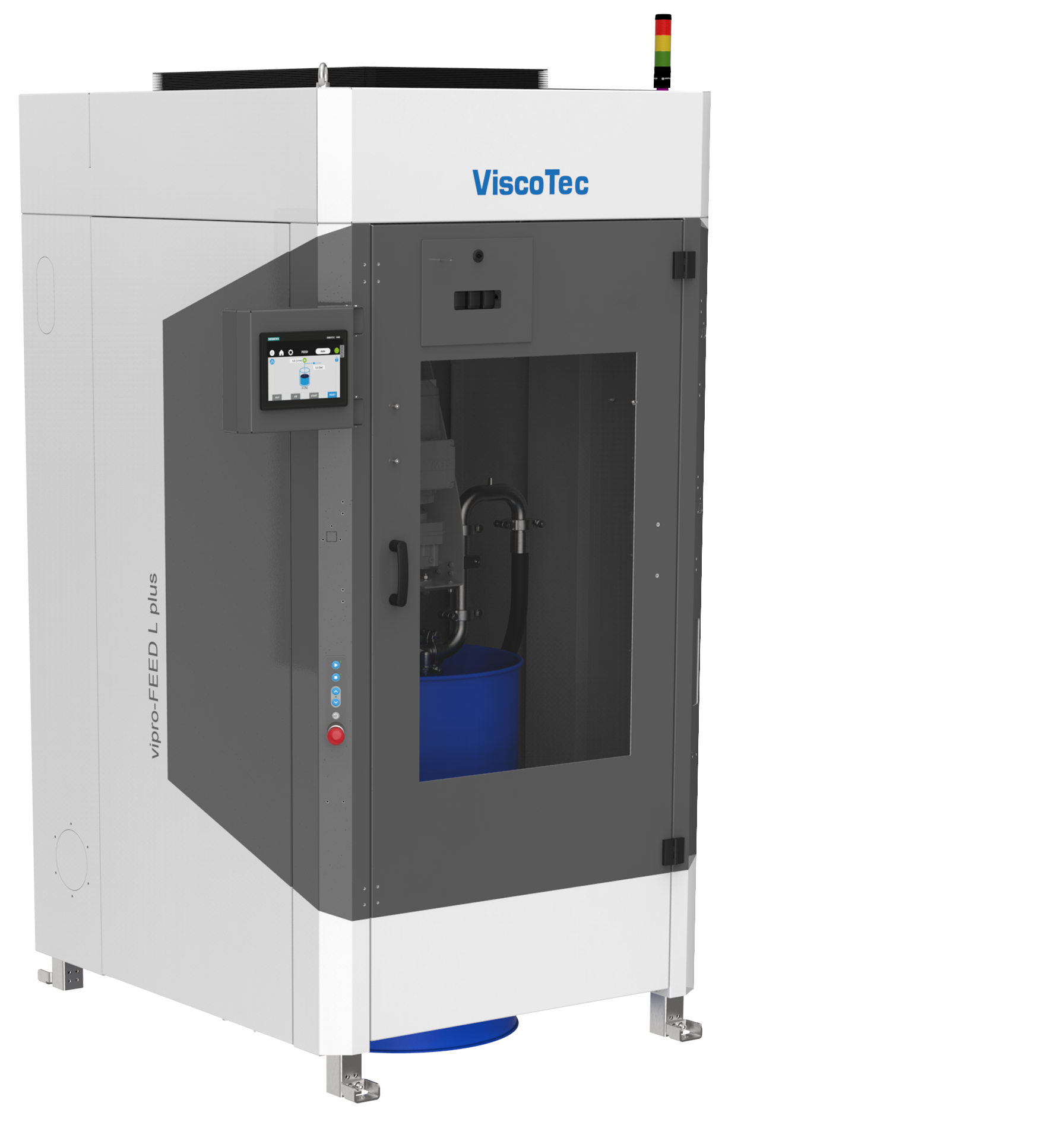

vipro-FEED L plus: Fully automated and uninterrupted emptying of 200-liter barrels

The new vipro-FEED L plus barrel emptying system allows for the efficient and safe processing of 200-liter barrels – ideal for industries such as electronics manufacturing, aerospace, automotive, and e-mobility.

This compact system offers:

- Maximum efficiency and automation – fully automated emptying ensures a consistent, bubble-free material flow, even with highly viscous materials.

- Integrated safety and user-friendliness – all standards are met, the systems are intuitive to operate, and no specialized personnel are required.

- Flexible, cost-effective solution – multiple loading options, compact design, and easy maintenance reduce operating costs and boost productivity.

Thanks to integrated sensors and a Profinet interface, the system can be seamlessly integrated into higher-level control systems. As a result, the vipro-FEED L plus offers maximum efficiency and process reliability for emptying 200-liter barrels. Technically, the vipro-FEED L plus is based on the concept of the smaller vipro-FEED M plus, which will be on display at the trade show due to space considerations.

Discover the dispensing technology of the future – at booth 435 in hall A4.