New benchmark for additive manufacturing in medical technology

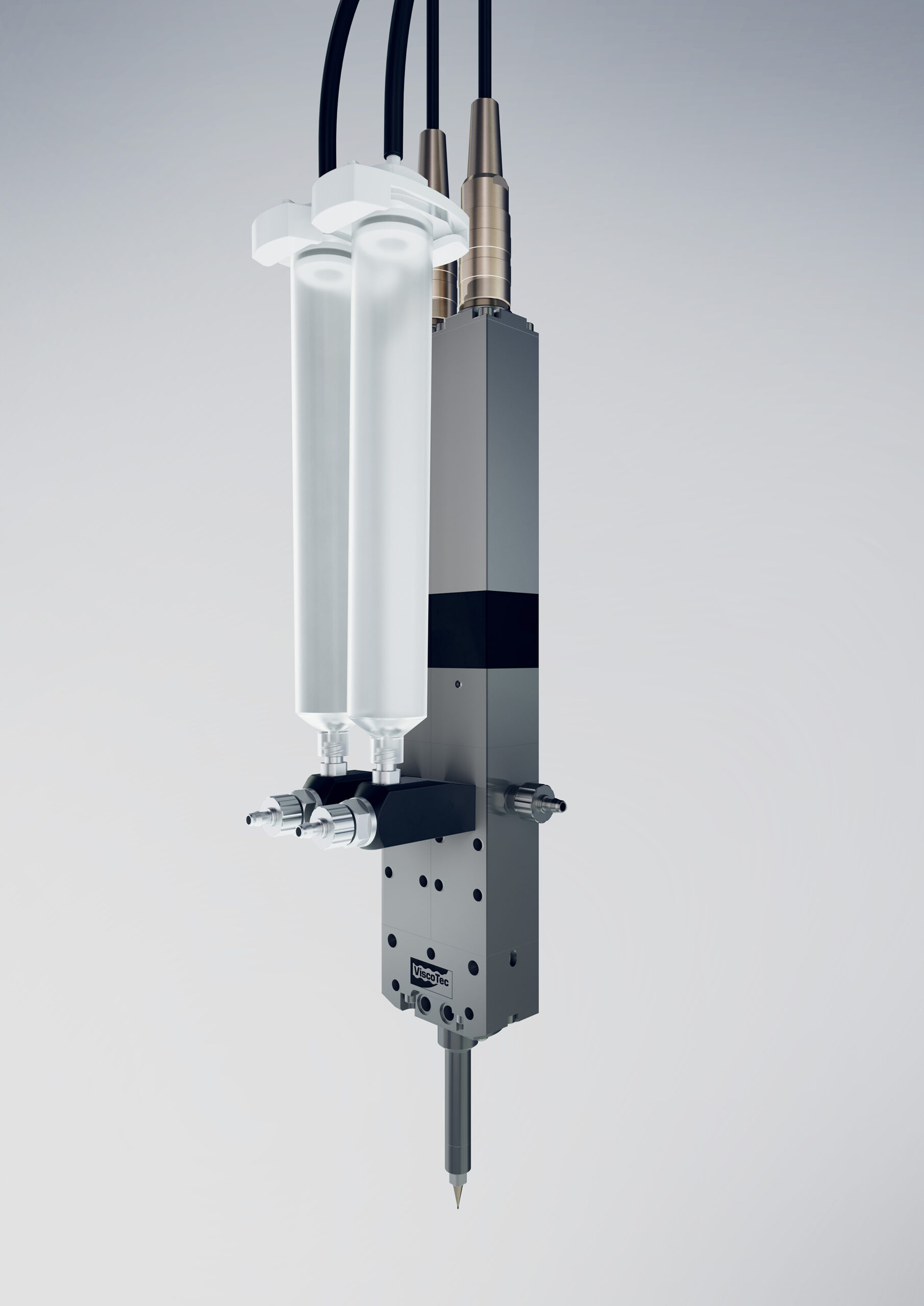

ViscoTec Pumpen- u. Dosiertechnik GmbH is expanding its portfolio in the field of 3D print heads: The proven vipro-HEAD models are now also available as a medical grade series. This means that print heads specially tailored to the requirements of the medical and medical technology market are now for sale.

For the highest demands in medicine and medical technology

The new vipro-HEAD medical grade printheads have been specifically developed for applications where safety, material compatibility, and patient-specific care are crucial. Product-contacting components are made of either stainless steel or elastomers and plastics with FDA certification. An autoclavable version that can be sterilized at up to 121 °C is also available.

Wide range of variants for flexible applications

The following print heads have been adapted or further developed as part of the medical grade series:

- vipro-HEAD 3 and vipro-HEAD 5

- vipro-HEAD 5/5 for 2-component applications

- vipro-HEAD 5 with heating function – in a standard version up to 70 °C and as a high-temperature version up to 110 °C

Wide range of applications of the medical grade series

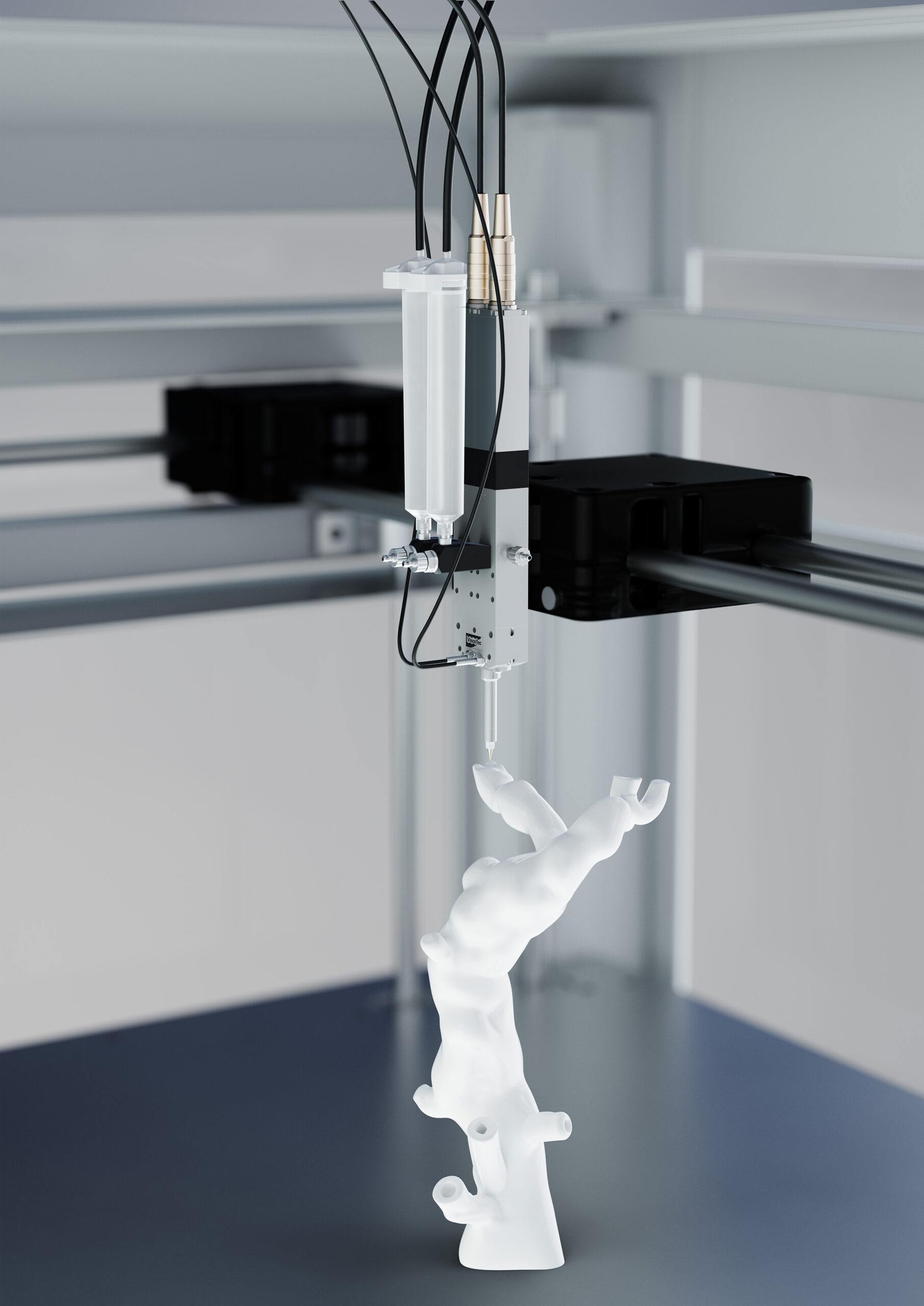

Thanks to these adjustments, materials that are of central importance in medical technology can be processed, including hydrogels, silicones, polycaprolactones, and ceramics. This opens up new possibilities in the additive manufacturing of patient-specific implants, prototyping, and the development of innovative therapy solutions – even in batch sizes of one.

Typical applications include:

- (Absorbable) implants, e.g., bone or breast implants

- Flexible implants such as silicone vascular structures

- 3D-printed tablets for individualized drug release

- Wearables and prototyping for medical devices

Technical Highlights

- Resolution: Line width from approx. 100–150 µm

- Flow volume: Up to 6 ml/min per print head half (12 ml/min for 2-component applications)

- Materials: Including hydrogels, polycaprolactones, silicones, ceramics

- FDA-certification for elastomers and plastics that come into contact with products

- New high-temperature variant up to 110 °C

Examples of applications for ViscoTec print heads

- 3Deus Dynamics, based in Lyon (France) uses our print heads to produce highly realistic anatomical models – such as aortas – for surgical training and surgical planning. These 3D-printed structures are also used in medical device testing, contributing to the reduction of animal testing and the reliance on cadavers. Discover their latest use cases on the 3Deus Dynamics website: Healthcare Applications | 3Deus Dynamics

- Healshape, also based in Lyon, uses our 3D print heads to manufacture hydrogel-based, resorbable breast implants that are customized for each patient and regenerate after implantation through the body’s own tissue. Thanks to the combination of 3D printing, patented, biocompatible hydrogel, and precise print head technology, individual, natural breast implants are created that are resorbed by the body within a few months. More information can be found on the company’s website: Healshape – Soft tissue natural reconstruction

“With the medical grade series of our vipro-HEAD printheads, we are taking the next step towards additive manufacturing in medical technology,” explains Johanna Bruckhuber, Business Development Manager “Components & Devices.” “This enables our customers to implement patient-specific solutions – from implants to individualized medicines – and thus makes an important contribution to the medicine of the future.”

Interested visitors can experience the new product live at COMPAMED 2025 in Düsseldorf (17–20 November, Hall 08B, Booth 8BC25) as well as at Formnext 2025 in Frankfurt am Main (18–21 November, Hall 12.0, Booth F119).