High-precision uniform material coating of bore holes and internal threads

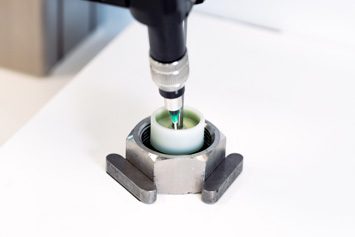

Combined with different ViscoTec dispensers as a material feeder, the Rotorspray vipro-SPIN enables volume-dispensed application of adhesives or viscous greases in bore holes or internal threads. The desired amount of material to be dispensed is applied in precisely defined quantities and with repeatable accuracy all round.

The internal contours are wetted evenly and over a wide area. This is a non-contact application. Due to the conical inner geometry of the spinner head, it is possible to use the Rotorspray in both vertical and horizontal orientation.

The vipro-SPIN is suitable, for example, for lubricants, greases and anaerobic or other adhesives – from low to high viscosity. A total of four different spin heads are available. For a flexible coating of interior cylindrical surfaces with a diameter of approx. 16 to 50 mm. A plug-in cable, available in different lengths, allows the Rotorspray to be easily integrated into various control unit systems.

Areas of application for the vipro-SPIN

The vipro-SPIN is always required when adhesives or other viscous materials are introduced into bore holes, internal threads, or ball bearings. Another possible application is to make a shaft-hub connection.

This is of particular interest, for example, in automotive engineering, engine construction or general industries, such as vacuum cleaner manufacturing.

Continuous spray pattern

The special feature of ViscoTec technology: A volume-dispensed application is possible with the Rotorspray. This means that the volume can be precisely defined via the dispenser, and the layer thickness of the material application is continuously uniform. Over- or under-dispensing is avoided by using a volumetric dispensing system instead of time-pressure systems. This is an advantage over the competition because the dispensing quantity cannot be precisely defined when using i.e., simple outlet valves and pressure vessels.

The ability to set and spray different volumes on one component offers a further advantage. An example to illustrate this: In an internal combustion engine, there are many bearings and bore holes on which blind caps are placed. These bearings and bore holes are of different sizes and therefore require different dispensing volumes. With the vipro-SPIN, the desired volume for each bore hole or joint can be precisely set and, if necessary, even changed during the process. This is easily set via the dispensing control. In this way, it is also possible to monitor whether and which quantity is being dispensed. For high process reliability.

Additional special features of the vipro-SPIN

In addition to single-component materials, the Rotorspray can even be used to spray two-component materials if required. The adhesive system or other two-component materials are fed mixed to the vipro-SPIN and applied by it to the component. Simple and fast disassembly of the spinner head or the dispenser itself allows uncomplicated cleaning of the components.

Martin Höpfinger, Product Manager at ViscoTec on the Rotorspray: “The vipro-SPIN is an excellent addition to ViscoTec’s product portfolio. It offers an extra solution and enables dispensing and material coating for internal geometries. In combination with a ViscoTec dispenser, this results in another customer-friendly dispensing system from a single source.”

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information